News

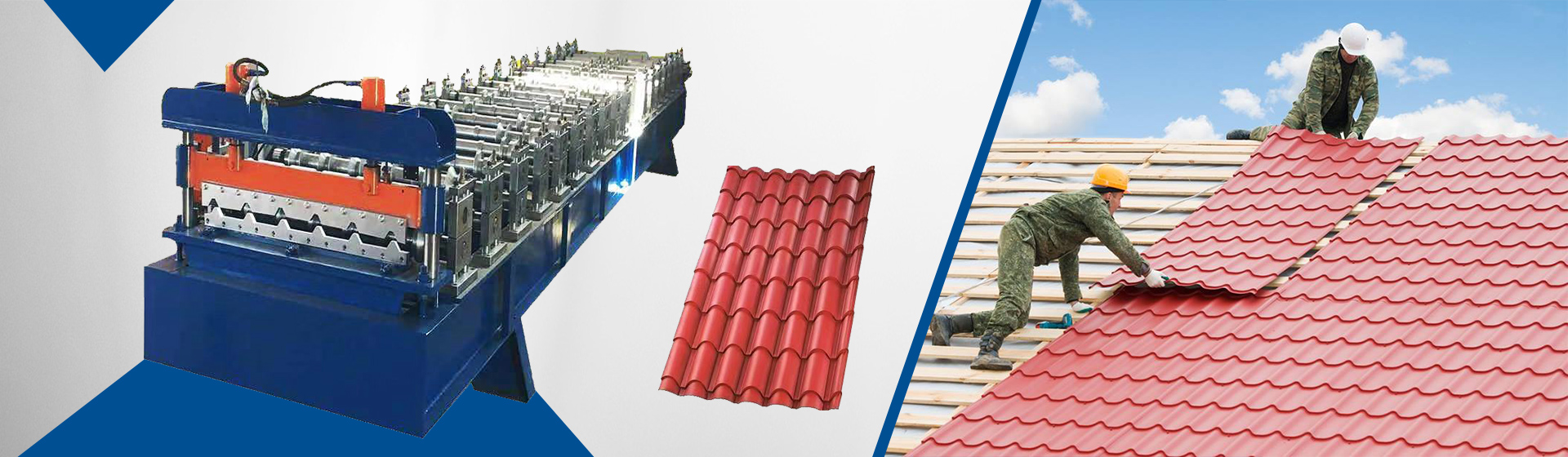

- Automatic roofing forming machineWe have a good quality and low price automatic roof tile forming machine. Our factory serves the new and old customers with the principle of lowest price and quality. The ridge tile forming machine adopts the roller forming technology and is combined with the die hydraulic forming. The products are widely used in the roof connection of architectural color steel plates. 1. Equipment installation dimensions: 8000mm × 1300mm × 1500mm 2. Equipment weight: about 4000kg 3. Total equipment power: 7Kw 4. Hydraulic power: 4Kw 5. Pressing machine pressure wheel number: 10 channels 6. Applicable plate thickness: 0.5-0.6mm 7. Applicable board width: 500mm 8. Product length error: ± 2mm 9.Electronic control system: The whole machine adopts industrial computer PLC control, fully automatic lengthening, cutting and convenient operation. This machine can be customized according to customer's requirements.

2019 10/05

- New bamboo glazed tile equipmentThe new bamboo glazed tile equipment is a new type of color steel equipment control system that can also complete the single board cutting function. The glazed tile pressing machine is divided into three parts: the roller forming part, the pressing part and the cutting part. The roller forming portion is dragged by the motor, and the chain drives the rollers to rotate. The pressing part is a hydraulic cylinder that drives the mold to move up and down, and can press the color steel into many sections, which are shaped like glazed tiles. The cutter part is a hydraulic cylinder that drives the tool to move up and down, and can cut the color steel tile. The production process of the new bamboo glazed tile equipment is as follows: the colored steel plate enters the forming part of the roller table, and after molding, it is pressed into the pressing part, and is pressed into a section of equal distance, and the cutter is responsible for the fixed length cutting. The execution part has inverter drive motor, hydraulic station motor, two hydraulic solenoid valves of the pressure type, and two hydraulic solenoid valves of the cutter. The detection part includes: a pulse encoder for detecting the length of the colored steel tile, a press-type upper and lower stroke switch, a cutter upper and lower stroke switch, a press-type upper and lower operation button, a cutter upper and lower stroke button, an emergency stop switch, a hydraulic start-stop switch and many more. PLC selects KDN-K306-24AR of KDN-K3 series. It has 14 inputs / 10 relay outputs, just to meet the input and output requirements. With the KDN text screen, you can complete parameter settings, alarm display, help information, production data display, and more.

2019 10/05

- Matters needing attention when operating color steel tile press equipment1 Pay attention to safety when the equipment is live. 2 Do not put your hands or foreign objects into the knife at any time. 3 The electrical cabinet should be protected from rain and sun; the counter should prevent hard objects from colliding; the line should be prevented from being broken by the board. 4 The machine is often lubricated with the moving parts. 5 Power off when plugging and unplugging the aviation plug

2019 08/09

- Common fault analysis of roll formig machine pressAll kinds of roll forming machine has many years of summary. In the process of using the tile machine, the following two points are prone to failure. 1. Hydraulic pump station failure: The hydraulic pump station controls the shearing system of the color steel tile press equipment. As the production time increases, the hydraulic pump station may not be oily or overheated, mostly due to poor contact of the solenoid valve. Or is it a problem with the quality of hydraulic oil. 2. Computer control system: The fault of the computer control system is generally caused by improper operation. When the equipment is sold, we will have a special technician to come to the customer to install and debug and teach the customer how to operate. However, it is impossible to avoid the novice, that is, the personnel who have not been trained by my technicians to operate the equipment, thus causing the program failure of the equipment computer control system.

2019 08/09

- How does the color steel tile machine work?The workbench of the color steel tile press has six processes, that is, the turning of the workbench (ie, the hexagonal runner). In addition to the first-level mechanical indexing and positioning, a set of precise positioning mechanism is also provided to ensure that each stamping process is completed. Accurate positioning of the table mold, the sliding table for mounting the upper mold is the box structure, the slide rail and the upper rail of the fuselage, the contact length is large, each stamping of the upper mold, the second stamping of the mud blank is the upper mold After the primary blank is in place, the upper die rises by 10 mm. Cold-formed steel is the main material for making lightweight steel structures, and is formed by cold bending of steel plates or steel strips. The wall thickness of the C-shaped steel machine can be made very thin, and the production process is greatly simplified and the production efficiency is improved. It can produce cold-formed color steel equipment of various profiles and different materials with uniform wall thickness but complicated cross-section shape which are difficult to produce by general hot rolling method. After the mud blank is fully exhausted, the upper mold presses the tile blank in place to return to the high position, so that the mold has a long service life and the quality of the pressed product is good. The color steel tile press will be equipped with a set of lubrication system. When the machine is running, it will automatically lubricate all the bearing bearings and the moving guides of the transmission gear mechanism.

2019 07/25

- Installation method of color steel tile pressing machine for color steel tile machineThe color steel tile pressing machine of the color steel tile machine has the following parts: a pulse encoder for detecting the length of the colored steel tile, a press-type upper and lower stroke switch, a cutter upper and lower stroke switch, a press-type upper and lower operation button, and a cutter upper and lower stroke. Buttons, emergency stop switches, hydraulic start-stop switches, etc. The implementation part of the color steel tile pressing machine has a frequency converter driving motor, a hydraulic station motor, two hydraulic solenoid valves of the pressing type, and two hydraulic solenoid valves of the cutting knife. (1) High-altitude bulk method of tile press The high-altitude bulk method refers to the method of assembling small units or parts (single rods and single nodes) directly at the design position. The high-altitude bulk method has two methods: full bracket (ie full-frame scaffolding) method and cantilever method. The full-support method is mostly used for assembling parts, while the cantilever method is mostly used for small units to fight at high altitude. Since the parts are assembled at high altitude, there is no need to use large lifting equipment, but a large amount of scaffolding material is required due to the large-scale assembling bracket. (2) Strip or block installation method Striping or block installation refers to the method of installing the grid into strips or blocks, which are respectively hoisted by the lifting equipment to the high-altitude design position, and then placed in an integral manner. The strip shape is divided into several sections along the long span direction of the grid. The width of each strip can be a grid to three grids, the length of which is the span of the short span of the grid, and the block shape is divided along the vertical and horizontal direction of the grid. The rear unit shape is a rectangle or a square. The weight of each unit is based on the lifting capacity of the existing lifting equipment on site. Slitting or splicing installation Most of the welding and splicing work is carried out on the ground, which is beneficial to improve the quality of the project and save most of the assembled brackets. Since the split singularity has taken into account the existing lifting equipment capacity on site, it can be fully utilized. Existing equipment at the construction site to reduce the rental fee for lifting equipment.

2019 07/25

- How Structural Insulated Panels WorkIf you've ever seen a typical house being built, at one stage in the process you probably saw a wooden latticework of spindly 2x4s outlining a shape somewhat reminiscent of a whale's ribcage. But although this method is currently the standard, there are other ways to build a home -- and some of them can save you quite a bit of money in the long run. One of these alternate techniques is to construct a house using SIPs, which stands for structural insulated panels. SIPs are prefabricated solid sheets of building material that are generally constructed of a foam core surrounded on each side by a layer of oriented strand board (OSB). They're most commonly used for walls and roofs, but can also serve as floors and foundations. The idea behind structural insulated panels was first conceived of in the 1930s, but the invention really took shape in 1952 with the creation of the first foam-filled SIP [source: SIPA]. The advent of CAD/CAMtechnology and CNC machining further energized the process. Using CAD (computer aided design) and CAM (computer aided manufacturing) software means the blueprints for an SIP house can be converted into detailed instructions for a CNC (computerized numerical control) machine. Then it can quickly and accurately whip out the exact components needed. This made the process more efficient and streamlined, minimizing waste and reducing cost. You might be wondering at this point: If SIPs were such a hot new idea, how come stick frame houses are still popping up like weeds? The answer, in a nutshell, is that building trends often shift at a glacial pace. SIPs met with success in the 1970s during the energy crisis, but as that faded away, so did much of the popularity of building energy-efficient homes. Since energy issues are just one of the many concerns touching today's markets, SIPs and similar building prospects are waiting in the wings, ready to make a big comeback. We'll get into the hows and the whys in a second, but first we'll take a look at some of the different materials that can be used to make SIPs on the next page.

2019 06/28

- What can I do to my roof to save on energy costs?Did you know that nearly half of the money you spend on utility bills goes toward heating and cooling your home ? In many American homes, energy costs are literally going through the roof. Your roof is your first -- and best -- defense against the summer heat and the winter chill. A low-efficiency, poorly insulated roof can let in too much heat in the summer, leaving you with huge air conditioning bills. It can also let off too much warmth in the winter, leading to astronomical heating costs. Spending a little bit of money on a good roof now can save you a lot on heating and cooling bills in the long run. An energy-efficient roof not only protects you from the elements, but it also keeps your home cooler in the summer and warmer in the winter. Energy-efficient materials are also able to withstand the constant bombardment of ultraviolet (UV) radiation from the sun, extending the life of your roof. he most energy-efficient roofing products have a high solar reflectance, meaning that they reflect the sun's energy back into the environment, rather than absorbing it. Reflective roofs can reduce the temperature on the surface of the roof by as much as 30 percent -- which means that less heat gets into your home. The most energy-efficient roofs also have high emittance, which means they're efficient at releasing any solar heat they have absorbed. Adding insulation can further increase your roof's energy efficiency. R-value measures the ability of insulation to resist the transfer of heat. In colder climates, insulation materials that have a higher R-value can help trap heat inside the home and lower home heating costs. Depending on where you live, you might get a financial incentive for making your roof -- and home -- more energy efficient. In California, for example, residents who increase the thermal value of their home's insulation get rewarded in the form of tax rebates. When choosing a roof, look for products that carry the government's Energy Star label, because they can save you a lot on energy costs. The government created the Energy Star program to help promote the use of energy-efficient products. Only roofing products that are highly reflective are given the Energy Star label. These roofs can reflect enough of the sun's rays to lower the temperature on the surface of your roof by as much as 100 degrees Fahrenheit (56 degrees Celsius) Pick your roofing material and color based on your location. Light-colored roofs tend to reflect heat and are good in warmer climates, while dark-colored roofs absorb heat and are better in cooler climates. If you live in a warmer area or have trouble keeping your home cool, but you don't want to splurge for a whole new roof, you can cover your existing roof with a light-colored coating to lower your cooling costs. Roof coatings can reduce the surface temperature on a roof by 50 to 80 degrees Fahrenheit (28 to 44 degrees Celsius).

2019 06/28

- 10 Best Roofing Materials for Warmer ClimatesWhen you consider how a building keeps cool, the most common thing that comes to mind is air conditioning. But the first real line of defense against the heat is a building's roof. And a hot day in the life of a good roof should include releasing -- not storing and absorbing -- the sun'srays. Think of it this way: If you're sitting on a chair covered in black fabric and you go to the kitchen for a cup of coffee, your chair will likely be warm when you get up -- and it will stay warm until you return. But if your chair is metal, clay, molded plastic or slate, for example, it might be slightly warm to the touch when you get up, but it will be entirely cooled by the time you return. Traditional shingle roofing materials hold and transfer heat in a similar way. Roofing tiles made of felt-like materials overlaid with asphalt and tar will hold heat, and even transfer it downward into a structure, while other types of roofing will reflect light and heat upward and away from a building instead. Roofing materials and colors impact how buildings -- and even entire cities -- handle heating and cooling. United States Energy Secretary Stephen Chu even suggested that painting all roofs and roads white or light-colored could reduce the electricity costs of running air conditioning by 10 to 15 percent [source: Connor]. Is it that simple? Before grabbing a ladder and a can of patio furniture paint and exterior primer, see what roofing materials and techniques -- from the traditional to the high-tech -- have proven to work well in warmer climates.

2019 06/28

- What are the different types of roofing nails?(roll forming machine accessories)Roofing nails are used in roof installation to fasten shingles, to install roofing felt for waterproofing and to attach roof tiles and sheet metal. There are different kinds of roofing nails, made of different materials and in various sizes. All roofing nails have wide, flat heads and short shanks. The tips of the nails are sharp and pointed for easy insertion so you don't break the shingles or damage the wood when driving the nails through. Different roofing materials require different types of roofing nails. Aluminum nails are good for metal roofs and shingles, but they are not recommended for areas where they can be exposed to chemicals or salt. If you live in a coastal area, use stainless steel roofing nails. Stainless steel nails are also good for fastening tiles and slate, or you can work with copper nails for standard roofing purposes. Galvanized roofing nails are steel nails that are zinc-coated. They hold up better against rust, and they can also be used for asphalt shingles. Another kind of classification for roofing nails is by size. Standard lengths are between 1 and 2 inches (2 and 5 centimeters) but they are also available at lengths of up to 6 inches (15 centimeters). The length of the nail is the shank, and the shank can also vary. Screw shank nails are twisted and have sharp diamond tips, and they are used to securely fasten wood roofs. Ring shank nails have a larger nail head; they are usually made of galvanized steel, which are strong and good for fastening shingles in areas with strong winds. The standard, cheapest and most commonly used roofing nails are smooth shank nails. They are generally made of aluminum, stainless steel or copper, and they're not as strong. The shank length you need depends on the roofing material. Use 1-inch (2.5 centimeters) nails for asphalt or fiberglass shingles; you`ll need longer nails for wood shingles, which are thicker.

2019 06/28

- How to Waterproof Your BasementIf your house doesn't have gutters, consider installing them or having them installed by a professional. DAVID HARTWELL/GETTY IMAGES The key to solving a leaking basement problem is to direct the water away from the house's foundation. Gutters can help a lot. Gutters catch rainwater and whisk it away through downspouts. If your house doesn't have gutters, consider having them installed. And this next step is critical: Attach horizontal drain extensions that are at least 4 feet (1.2 meters) long to the downspouts. These will direct the water away from the edge of the home's foundation and away from the basement [source: familyhandyman.com]. If you already have gutters, clean them. Gutters won't work if they're crammed with leaves and branches. Specifically, unclog the mess where the gutters meet the downspouts. If not, when it rains, the water can cascade like a mini Niagara Falls straight down to the edge of your foundation [source: Brasler]. Another way to direct water away from your home's foundation is to regrade the ground away from the foundation. This is more involved than simply adding gutters and downspouts, but it can help. The slope should be at least 6 feet (1.8-meters) wide, dropping down to about 4 inches (10 centimeters) away from the foundation. You can also cover the slope with plastic sheeting for added protection. Hide the sheeting with dirt and simply plant grass over it, or throw mulch or stone on top [source: familyhandyman.com]

2019 06/28

- How to Install Metal Roofing sheetAlthough the initial monetary outlay is greater for metal roofing than for shingles, over time the cost justifies itself. Metal roofing holds up much better than other types of roofing under dangerous weather conditions, has a top fire safety rating and is waterproof. Installing a metal roof is a lot easier than it sounds [source: Sheet Metal Roofing machine, DIY-HQ]. Here's what you'll need: Extension ladder Metal roofing Metal trim and edging Drill with bits of various sizes Heavy-duty hammer Snips for cutting metal 1 ¼ inch (3.2 centimeter) roofing nails Screws for metal roofing 10 pounds (4.55 kilograms) of 3-inch (7.6-centimeter) long head screws Tarpaper Follow these steps: Remove the old shingles. Spread the tarpaper over the wood of the roof to create a new waterproof base. Install the metal edging around the roof's perimeter using 1 ¼ inch (3.2 centimeter) roofing nails. Start with one side of the house, at the top of the roof. Screw a metal sheet into the wood of the roof (through the tarpaper). Screw in the next sheet, making sure that it overlaps the first sheet. Repeat the process until you are down to the last sheet to be installed at the bottom of the roof. Measure the area still left to be covered on the roof. Using the snips, cut the last sheet to the correct size and screw it into place. Repeat steps four through six on the other side of the house. Place metal trim along the edges and at the top peak of the roof. Bend the trim to make it V-shaped, fit it over the roof's ridge and screw it down. Make sure to screw down all the metal trim and bottom sheets.

2019 06/28

- The knowledge of machine-relatedFunction getting machines shows interested planting notice as well as interest rates from the new customers up to each of our globe. For many women will have payed steady put attention located on the entire market place created by move expanding system, you will need worked out in may need to seek a numerous varieties of list xinnuo roll forming machine entirely on market place. These particular strain raising machineries but not now appear in alternative spot prices though are purchasable regarding quite a few dimension as well as conditions. From the time strain progressing equipment was basically without a doubt any kind of very position by using lots of market sectors. It's noticeable previously popular game that most assorted types of rotate having machineries might be frequently applied in various kinds of companies. Taking into consideration begin generating equipment runs this kind of huge aspect in your standard of living, it's of great importance and necessity that will become familiar with lot more concerning the entire rotate maturing devices operate, specially the category as well as primary very good reasons at shoot growing systems. In the, we all ensured so that you get acquainted with their possibilities of i would say the entire function establishing machinery. Presently the very entire associated with retract creating systems is very much more than just saturated. On top of that, relevant applied science and craftsmanship happen to quite possibly be as of late more aged. Additionally, there is a large interest rate at throw constructing devices within the whole area. To that end, we certain that the most important entire begin expanding devices land get hold of an absolute vivid foreseeable.

2019 05/14

- The knowledge of roofing sheet machine-relatedFunction getting machines shows interested planting notice as well as interest rates from the new customers up to each of our globe. For many women will have payed steady put attention located on the entire market place created by move expanding system, you will need worked out in may need to seek a numerous varieties of list xinnuo roll forming machine entirely on market place. These particular strain raising machineries but not now appear in alternative spot prices though are purchasable regarding quite a few dimension as well as conditions. From the time strain progressing equipment was basically without a doubt any kind of very position by using lots of market sectors. It's noticeable previously popular game that most assorted types of rotate having machineries might be frequently applied in various kinds of companies. Taking into consideration begin generating equipment runs this kind of huge aspect in your standard of living, it's of great importance and necessity that will become familiar with lot more concerning the entire rotate maturing devices operate, specially the category as well as primary very good reasons at shoot growing systems. In the, we all ensured so that you get acquainted with their possibilities of i would say the entire function establishing machinery. Presently the very entire associated with retract creating systems is very much more than just saturated. On top of that, relevant applied science and craftsmanship happen to quite possibly be as of late more aged. Additionally, there is a large interest rate at throw constructing devices within the whole area. To that end, we certain that the most important entire begin expanding devices land get hold of an absolute vivid foreseeable.

2019 04/19

- New type roofing capping machineRecently, a new type of roof-covering machine developed and produced by Shenyang Beiya Beverage Machinery Co., Ltd. was unveiled at the "Dairy Products Exhibition". This type B roof-type packaging machine overcomes the technical problems that the roof-shaped packaging machine cannot be hot-filled, can not be capped, does not apply to the B-type box, and can make roof-shaped packaging products stored at room temperature for 3-6 months. B-type aluminum foil roof type packaging machine solves the problem that the fifth side of the carton is susceptible to leakage due to stress concentration. At the same time, all the cross-sections of the roof package that contacted the liquid were hemed so that the liquid did not penetrate the inside of the paper card from the cut surface; this caused the cartons to become soft, damp, deformed, and deteriorated. The lid of the capping machine is loaded into a fixed container in the equipment, sent to the capping station through a slide, and ultrasonically welded to the box. The entire production process is from box making, capping, filling and sealing. Full computer control of printing date, touch screen display, random recording of equipment status, and automatic oiling, automatic fault alarm and diagnosis and technical guidance processing, will not affect the output and quality due to operational faults. In addition, for ordinary roof packages must be stored under refrigeration, short shelf life (about 10 days of fresh milk, yogurt about 20 days), the problem of a small sales radius, technicians will be coated with a layer of aluminum foil in the middle of the B-type roof box, you can Blocking light and oxygen, therefore, increase the strength of the roof package, extend the shelf life, and ensure that the product is stored at room temperature for 3-6 months. At present, the company can achieve the same capacity of 200 ml, 375 ml, 500 ml, 750 ml, and 1000 ml. At the same time, the company can choose between capped and uncapped functions. In addition to filling yoghurt and milk beverages, North Asia roof pack filling machines can also be used to fill liquids such as fruit juices, soy sauces, liquors, and oils, opening a wider market for roof packages.

2019 04/18

- Part of the main technical parameters of sheet metal stretching machineItem different stretching machine column main technical parameters 2.5MN 4MN 10MN 60MN Tensile plate thickness/mm 0.3~4 0.5~7 4~12 5~150 Tensile plate width/mm 500~1500 1000~2500 1200~2500 1000~2500 Stretching plate length / mm 2180 ~ ~ ~ 20000 greater tensile speed / mm. S-1 5.6 5~25 12 5 Large Stroke Stroke/mm 320 1200 Transmission Oil Pump Pressure/MPa 20 20 86 20 Transmission Oil Pump Capacity/L. Min-1 50 pump motor power/kw 20 16 pump motor speed/r. Min-1 970 685

2019 04/18

- Research and Development of Automatic roll Forming MachineCore Tips: High system reliability measures. The technology can be applied to refrigerators, pharmaceuticals and chemical industries. Automatic Vacuum Plastic Forming Machine (abbreviation referred to as Blister Machine) is a large-scale equipment for thermoforming processing of molds for thin and soft non-metallic materials (mainly thermoplastics). It is mainly used for the production of refrigerators and semiconductors. High system reliability measures. The technology can be applied to refrigerators, pharmaceuticals and chemical industries. Automatic Vacuum Plastic Forming Machine (abbreviation referred to as Blister Machine) is a large-scale equipment for thermoforming of molds for thin and soft non-metallic materials (mainly thermoplastic plastics). It is mainly used for the production of refrigerators and refrigerators for semiconductor refrigerators and refrigerators. lining. At present, in domestic refrigerator production lines, automatic vacuum plastic molding machines mainly rely on imports from countries and regions such as Europe, the United States, Japan and South Korea. After deeply understanding the thermoforming processing technology of thermoplastics and the main functions of the entire control system of imported equipment, the author developed the automatic three-station vacuum blister using the industrial computer as the core, in accordance with the specific requirements of Hebei Aokelai Electronic Refrigerator Co., Ltd. Forming machine, the system can achieve 208 pieces of far-infrared heating plate sucker is completed, when the material is in place, used to press the sheet into the drive chain flap cylinder action, after pressing the sheet material feeding motor starts, the sheet Send to heating station. In this station, the heating cylinder drives the upper and lower heating plates to advance and heat the sheet according to a preset time and power. After the heating is completed, the sheet is driven into the forming station by the chain. Because the molding area of the refrigerator liner is large and the molding depth is deep, the molding process is difficult to control, so the molding station is the key station for the most actions and the most complicated process of the vacuum molding machine. The molding process includes the upper mold press and the sheet material. Blowing, mould rising, vacuum forming, sheet cooling, mould stripping, etc. In this way, the blank of the refrigerator liner is obtained, and the refrigerator liner is formed after the trimming, punching, and other post-processing. 2 The hardware structure of the control system The main issues to be considered in the control system design are to reduce costs, improve reliability, and have a friendly and intuitive control interface. For this purpose, a control system with an industrial control computer as the core is adopted, and its hardware structure is as shown. The system takes the research company EVOC810 IPC as the core, adopts two data acquisition cards plus four terminal board optimal control schemes, and successfully solves 20 output signals, 22 input signals and 208 far-red heating controls and 22 The logical control of the road input signal and the 20-channel output signal has reached a relatively high level in terms of economy, reliability, convenience, practicality, and advancedness. 1 Typical Station The machine is mainly composed of 3 loading stations, heating stations and forming stations. The 3 stations are relatively independent and can perform their own actions at the same time. The sheet is transported by the toothed transmission chain. , as shown. The feeding of the machine is driven by the feeding cylinder to control the vacuum external heating plate. PCL812PG is a multifunctional data acquisition card developed by the company. It has 16 DI/DO channels, 8 differential mode AD inputs, and 1 12-bit DA output. The A628 is a digital-to-analog conversion card from ICP DAS and has 8 channels. The DA output and 16 DI/DO channels, the total number of digital input/output channels of both cards are 32 channels, which fully meets the design requirements, but the 208-channel analog control cannot be solved. To this end, the author carefully studied the thermoforming process and designed the LF398SH terminal board. The 208 heating plates are divided into upper and lower two layers, each with 104 blocks, composed of 8 rows and 13 columns of heating blocks. The outermost heating block is mainly used for isolation of temperature zones, that is, the heating temperature of the sheet is isolated from the ambient temperature, so the most A heating block in the outer layer can be regarded as a control point in the control. Since then, the upper and lower layers have been composed of 6 rows and 11 columns plus 1 control point, and each layer has 67 control points totaling 134 points. Even so, simply using 9 DA outputs on 2 cards will still not solve the 134 control points. Taking into account the characteristics of the 1F398 sample-and-hold device, 9-channel DA and 16-channel DI can be used to control the 145 heater chips in a cyclic scan output mode. The control principle is: the LF398's sample-and-hold characteristics are controlled by high and low levels, and high power. Flat sampling low-level hold, when the first 9-circuit DA output of industrial computer, using the first DO output on April 2005 China manufacturing information. 119 samples, hold, and then control the second 9 DA output, and then use the second DO output sample, hold, and so on until the 16 DA output of the 16th DO, constitute an output scan cycle, complete the 145 Block heater control. According to the characteristics of the LF398 and the size of the retention capacitor, the scan time can be determined. 3 software design of the control system The current popular development tools can almost complete the task of this topic, such as VB, Delphi, VC and configuration software, but due to problems of VB and Delphi in version compatibility, hardware accessibility, etc. And the cost of the configuration software, and ultimately chose Visual C + +6.0 as a development tool for the system, it has the characteristics of short code execution, fast execution, and can use MFC library with APP-Wizard, Classizard and AppStudio To greatly improve the development efficiency. The software of this control system is a desktop-level application with a Windows-style friendly interface. The development process mainly involves switching and analog I/O operations, the design of multi-threaded programs, database access, and the use of timers. The space is no longer exemplified by the source code of the program. The system has the following features: With the Chinese interface, the window layout is consistent with the actual layout of the heating plate, and the operation and parameter modification are very convenient. The system can accurately control the temperature of each heating plate on the heating plate, and automatically memorize its control parameters. It is not necessary to re-enter the temperature control parameters every time the product is changed. Simply input the corresponding mold (or sheet) Code can be, the interface is as shown. Parameter modification interface. It is convenient for manual and automatic conversion. The manual mode is mainly to realize the manual single-step movement of various moving parts to facilitate the installation, debugging or some special needs of the equipment. The automatic mode means that the IPC automatically completes all the logic actions of the whole machine during normal work and produces a qualified The product's typical interface is shown. The single-step action interface can realize the automatic monitoring of the working status of the whole machine. Problems (such as the empty of material, failure of a certain action, or the disconnection of a certain heating block, etc.) can be automatically shut down and alarmed. Greatly reduce the operation buttons of the device, simplify the control circuit and reduce the failure rate. With the exception of the power switch and emergency button, most operations can be done via the computer keyboard or by clicking on the on-screen menu with the mouse. It can automatically record the output per class and daily output, and can print out the report. 4 Reliability Measures The system integrates data acquisition, control, display, printing, and management into one, with no intermediate links and communications equipment, and thus a high cost performance ratio. However, because the control and management are highly concentrated in IPCs, the system risks are more concentrated. To solve this problem, the following measures are taken. In the field environment, electromagnetic interference and voltage fluctuations may cause the electronic components to deviate from the original working conditions, causing performance fluctuations, affecting system accuracy and product stability. Therefore, the installation and wiring of sensors and meters should try their best to avoid strong electromagnetic fields, and use high-precision power supply; IPC is powered by an isolated regulated power supply to avoid the interactive interference of the power supply; the input and output of the signal adopt optocoupler isolation device; Use a shielded cable to connect the shield to a little ground to avoid ground loop currents. These measures can effectively reduce electromagnetic interference in space and power. Automatic, manual control of backup redundancy, each execution has a manual button, once the system failure due to virus attacks and other reasons, you can use the manual button to continue production. Each heater chip corresponds to an ammeter for monitoring the on-off and current magnitudes, so as to avoid a large amount of waste products due to continued production after the heater chip is blown.. In order to improve the reliability of data acquisition, multiple (up to 1000) samplings are used and Digital filter technology to eliminate errors caused by singular point data and random interference. 5 Concluding remarks This system has been put into operation for half a year. It has stable operation, high production efficiency, and good economic returns. It only saves electricity, which amounts to 180,000 yuan per year and is well received by users. The development model and frame structure of this system can also be promoted and applied in the fields of medicine and chemical industry.

2019 04/05

- Lobo Parker LW-30T Carton Forming Machine Furniture OpenerCarton forming machine and carton opening machine refers to the automatic unpacking, forming, and bending of the bottom flap. And now the next part of the tape is to be glued, the cardboard box will be folded into a cardboard box, the bottom of the box is folded according to a certain program, and sealed with tape and then delivered to the special equipment of the boxing machine. Automatic carton forming machine and automatic carton opening machine are assembly line equipments for automatic unpacking of large quantities of cartons, automatic folding of lower covers, and automatic sealing of bottom tapes. The machines are all controlled by PLC display screens, which greatly facilitates operation and are essential for automated scale production. device of. According to the product line can be divided into: carton forming machine, carton forming machine, packing machine, cartoning machine, paper piece packing machine, unloading machine and so on. According to the degree of automation of the machine can be divided into: automatic molding machine, automatic carton molding machine. Vertical cardboard storage mode, and added at any time, without stopping; when Transform For carton size for the same time and use of packaging carton sizes, the use of manual adjustment (the time required for only 1 to 2 minutes); native With rational design, the suction box, molding, and back cover are processed automatically at one go; the performance of the parts is precise and durable; the operation process is vibration-free; the operation is stable and the service life is long;the machine is controlled by a PLC man-machine interface display screen with high performance, high speed, and efficiency. High; carton sealing tape at both ends of the folding angle length 50 ~ 70mm, can be customized 80,100 MM; can stand-alone operation, but also supporting the use of automated packaging lines. parameter Absence of tape and carton when the automatic alarm power 380V, 50Hz, 2.5KWpressure 4-8 kg / square cm tape width 4.8-7.2cm molding speed 20 to 60 cases / minute (according to specifications) tape length <= 2000m with hot melt machine Any brand of machine can match carton specifications Maximum size: L 150mm~506mm W 150mm~405mm H 102mm to 405mm external dimensions Length 3000mm, width 2000mm, height 1700mm machine weight 850kg

2019 03/22

- sandwich sheet forming machine loading

2019 02/20

- Angle Chi forming machine debuggingAngle Chi forming machine debugging: Angle Chi forming machine equipment - Angle Chi forming machine plate deviation test method, such as the plate running to the right, left corner of the pad (feeder), or fall to the right bottom flat. The first row and the last row of the angle chi forming machine equipment find a good center, and then tighten the two sides of the lock mother, in the center of the middle wheel before and after pulling a straight line, adjust the gap between the upper and lower shafts, then Can adjust the machine along the straight line. Those who do not understand the structure, performance and operation instructions of the angle forming machine must not start the machine. The angle forming machine must not work beyond the minimum closing height. That is, the minimum distance from the bottom of the sliding box to the working surface should be 290. The height after the upper and lower molds are clamped is required. In addition, the thickness of the upper and lower plates plus the thickness of the slabs are not allowed to exceed 290?, and the design should be designed according to this requirement in order to avoid machine accidents. Always pay attention to the observation, the sliding box and the height of the lubricant on both sides of the body. Equipment should be wiped regularly, kept clean, no muddy water is allowed. Firstly, the angles of the four corners of the front and rear rakes of the angle forming machine are the same from the height of the upper end of the shaft, and then from the first row to the last row, a straight line is straightened. Check whether the lower shaft is On a straight line, adjust the left and right sides of the lower axis to level. The demand for Kok Chi molding machines mainly focuses on high-end products such as medium and large-sized and heavy-duty machines. Although the import volume and import amount of Jinjia and Jinchee in China have decreased in 2007, the growth rate of machining centers and milling machines is still positive. It shows that China`s demand for high-end machine tools is still very strong. In order to meet the needs of the market, the capability of R&D and innovation of China's machine tool companies has been greatly improved, the product structure has been further optimized, and the market competitiveness has been further improved. From the perspective of market share, domestic share Finally, it accounted for more than 50% of the market share of Kok Chi forming machines in China, reaching 57.4%, which was the first breakthrough in 2001. In the future, the space for China's machine tool substitution import is still very large. From the perspective of specific products, the market capacity of Kok Chi forming machines The import and export deficit for larger lathes is not large. Angle Chi forming machine adopts Taiwan Delta DVP14ES host computer, using the text screen display of the electronic control system, easy to operate, easy to use. The angle Chi forming machine uses high-level automatic control software to achieve the production of information management; The entire unit automation control system The use of a highly integrated network makes the performance of the automation system more superior. The color steel tile equipment also has the advantages of operation, maintenance, maintenance, mechanical debugging and easy mold replacement. The color steel tile full steel structure workshop frame, single color steel plate steel structure Workshops, multi-span steel structure workshops, timber-lined beam plants, and villa-style color steel houses are connected with color steel ceilings, roof tops, large-span factory buildings, and light steel structures. The angle forming machine also has the advantages of operation, maintenance, maintenance, mechanical debugging, easy mold replacement, etc. The color steel tile full steel structure workshop frame, single-sided color steel plate steel structure workshop, multi-span steel structure workshop, and wooden traffic beam Plant, villa-style color steel house with color steel plate canopy, roof plus layer, large-span factory buildings, light steel structure ring shed. Angle Chi forming machine can be installed separately, but it needs manual loading and unloading of blanks. It can also be configured with automatic loading rack and unloading manipulator and extruder, cutting machine, sending machine and wagon conveying line. The production line completely eliminates the need for manual operation. Compared to the ceramic tile automatic pressing mechanism, the structure of the angle roller forming machine is relatively simple. The structure principle of the cement tile pressing machine is relatively simple. It is mainly composed of a hydraulic pump, a hydraulic sliding plug, and a fixed pressing table. , The activities of ring, pressure tile mold and other components. Its working principle is the current stage of the process of raw materials into the next mold, the hydraulic pump drive pressure tile automatically under pressure, cement sand in the role of pressure is filtered more Moisture and compacted cement tile products with a certain strength

2019 02/03

Email to this supplier